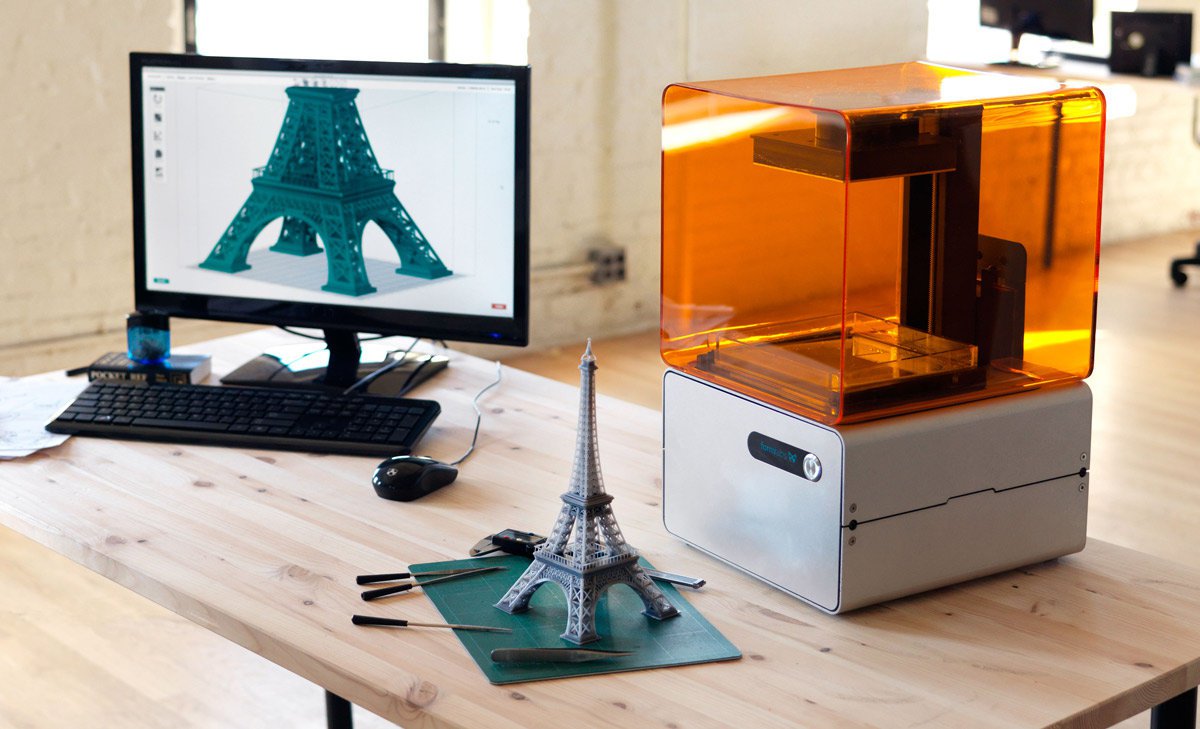

Before we start, here’s a glimpse of some cool stuff we 3D Printed at Tinkerer’s Lab!

Picture Credits - Dhruv Shah

3D Printing is an example of additive manufacturing. Additive Manufacturing is the means of creating an object by adding layers to it. Here’s how a single nozzle 3D Printer works.

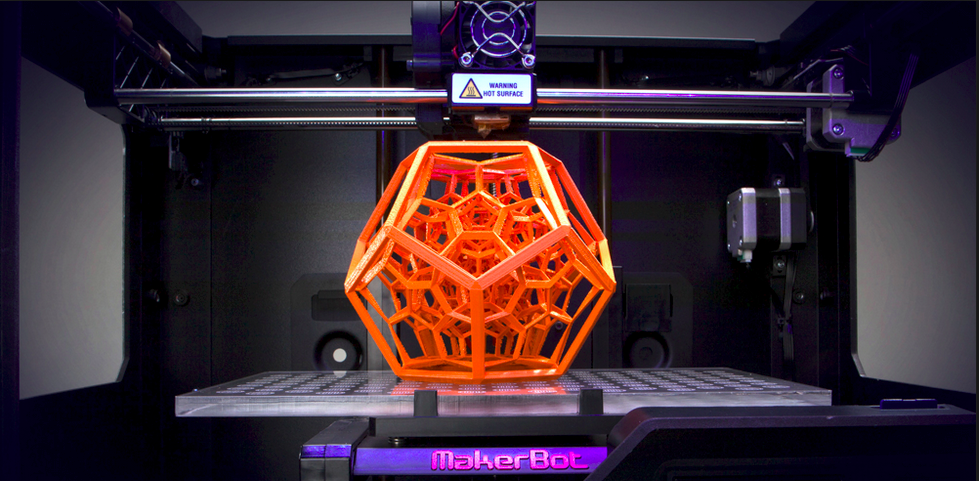

The most commonly used technology in this process is Fused deposition modeling (FDM). FDM includes injecting molten plastic (PLA and ABS are the most commonly used materials) in thin strands close to each other. We can manually set the density and other parameters in the software. The software that we have in TL is MakerBot.

The heating filament in our 3D printer heats up the wire near the nozzle to 230 degrees. The molten wire then comes out of the nozzle. The nozzle moves only in the X and Y directions, while the base moves in the Z direction. There are two motors in the part containing the nozzle, and two fans as well. Also, a material such as cellophane is attached to the base plate to facilitate removal of the 3D printed object from the base plate.

Calibration of the Printer- The printer has to be calibrated before it starts printing. The Printer first checks if the base is horizontal or not. To do so, the nozzle moves to three points first, directly above the three screws in the base plate. We will need to manually check the alignment by passing a thin sheet of paper between the nozzle and the base plate. If the paper passes through with some friction at all the three points, then we can assume that the base plate is horizontal. However, just to be sure, the printer makes us check at two other spots as well.

While printing solid objects, the printer is clever enough to use the least amount of material possible. Say for example, we want to 3D print a solid cube. What the printer does is, it’s prints the top few and bottom few layers as continuous solids. In the middle layers, it prints out honey-comb structures (hexagonal). Hexagonal structures are the most commonly used ones, though we can change the settings any time from the software.

Use of rafts in 3D printing- When we have to print an object, and the bottom of the 3D printer is a non-heating one, we’ll have to use a raft to prevent warping. The raft is larger than the actual part to be printed, and hence provides more adhesion. While 3D Printing once, the raft didn’t get printed due to some reason, and the actual object that we wanted to print got bent from the first layer itself, thus spoiling the entire object. That shows the importance of a raft. The raft thickness can be set from an option in MakerBot.

If the wire gets stuck, or if you wish to change the colour of the wire, then you’ll have to select the Unload/Load option in the 3D Printer. It’s usually present under the option named ‘Utilities’.

Use of support structures- If we have to print a structure like this-

we’ll need good supports. If there are no supports, the heated material flows a little more down before settling, which spoils the structure.

Advantages of a double nozzle printer- We can print out bi-coloured stuff! Also one of the major reasons that a double nozzle printer is used is because the second material used is soluble in a specific liquid. Hence, the printer prints the raft and support structures using this compound. Once printed, the whole structure is passed through the liquid and the support structure dissolves off leaving the design itself.

So, what would you like to 3D Print?